Flipchart Friday

Steel vs Concrete

By Leah Ewart

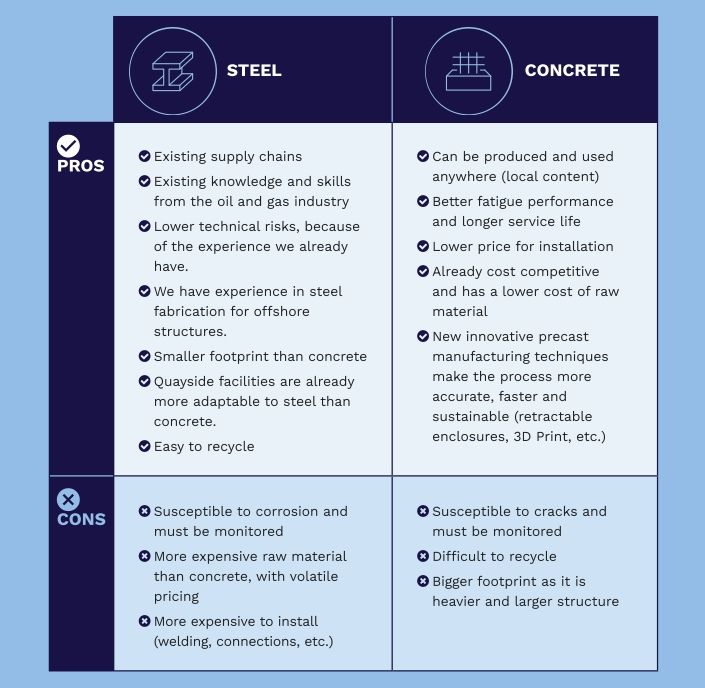

In this article we look at steel and concrete, and their uses for offshore wind foundations.

Overview

Steel is a very versatile material available in multiple different sections, such as flat plate and a variety of engineering structural beam sizes and different cross-sections.

Concrete is a non-homogeneous composite material with the compressive loads taken by the aggregates and cement matrix and the tensile loads carried by the embedded steel rebar.

Taken from the Empire Engineering Guide to Offshore Wind Foundations

Advantages and disadvantages

Concrete is highly resistant to corrosion, unlike steel, which gives it the advantage in the harsh offshore marine environment. It’s also more durable against fatigue damage. However, a steel structure will always be lighter than the equivalent concrete and is likely to be quicker to construct due to the time taken for activities such as placing rebar and pouring the concrete and waiting for it to cure. Local content is to some extent driven by local conditions.

However, there are very few markets that have the capability of producing enough steel required for a multi gigawatt wind farm. There is, however, usually a good local supply of concrete aggregates and cement materials which gives concrete the edge in this respect. Overall costs will be very dependent on the individual project specifications and activities such as placing rebar and pouring concrete are labor intensive which can increase prices in markets where labor rates are high. However, concrete itself is a low-cost material and historically is less volatile in pricing than steel. Therefore, concrete is often the economic option.

Finally, carbon content. Again, the embodied carbon will be very dependent on the individual project specifications. However, the emissions associated with the production of raw concrete materials are lower than those associated with the production of steel.

Therefore, a locally produced concrete structure is likely to have a lower overall carbon footprint than a steel structure where steel materials, and even the structures themselves, have to be transported over long distances.

In conclusion

To date, offshore wind foundations are almost predominantly constructed out of steel, and for structures such as monopiles and jackets, it’s difficult to see that changing due to the well-developed manufacturing methods which can produce large amounts of steel tubes in a cost-effective manner and the structurally efficient designs that can be created out of steel sections.

Concrete, however, comes into its own when weight is an advantage, not a disadvantage, such as for gravity bases. Concrete will also likely have a large part to play in the ever-growing floating foundation industry, where the mass of concrete is useful for hydrodynamic stability and therefore the advantages of concrete will likely outweigh the advantages of steel.

Empire specialists can effectively and efficiently assist with your offshore wind project. To find out more, please get in touch with the team at Empire Engineering.