By Aaron Zigeng Du.

Floating offshore wind

Floating offshore wind is a leading technology in the renewable energy sector. Since the world’s first commercial floating offshore wind farm Hywind Scotland with a capacity of 30 MW was commissioned in October 2017, Floating wind is growing at a rapid pace and expected to reach 4GW capacity by 2030 and continue to grow to 30GW by 2040 worldwide.

Deep water floating offshore wind turbines are installed farther offshore in a deep-sea environment to capture strong and steady winds. They are subject to extreme sea environmental conditions and high dynamic loads caused by wind, wave and currents. The stronger waves and gusts in conjunction with the higher and heavier turbine would lead to higher structural risk of floating wind foundation than that of bottom-fixed offshore wind foundations, such as monopile and jackets. With the increased turbine value and potential significant financial impact of unscheduled downtime, attention should be paid to the optimised design and safe operation of floating wind foundations.

A risk-based FOWSIM system can help wind farm owners, operators and other stakeholders better understand the structural risk, effectively manage structural integrity, and make informed decisions to ensure the assets’ fitness-for-purpose across the whole lifecycle of floating wind farms.

The structural risks of floating wind

Increased O&M cost and loss

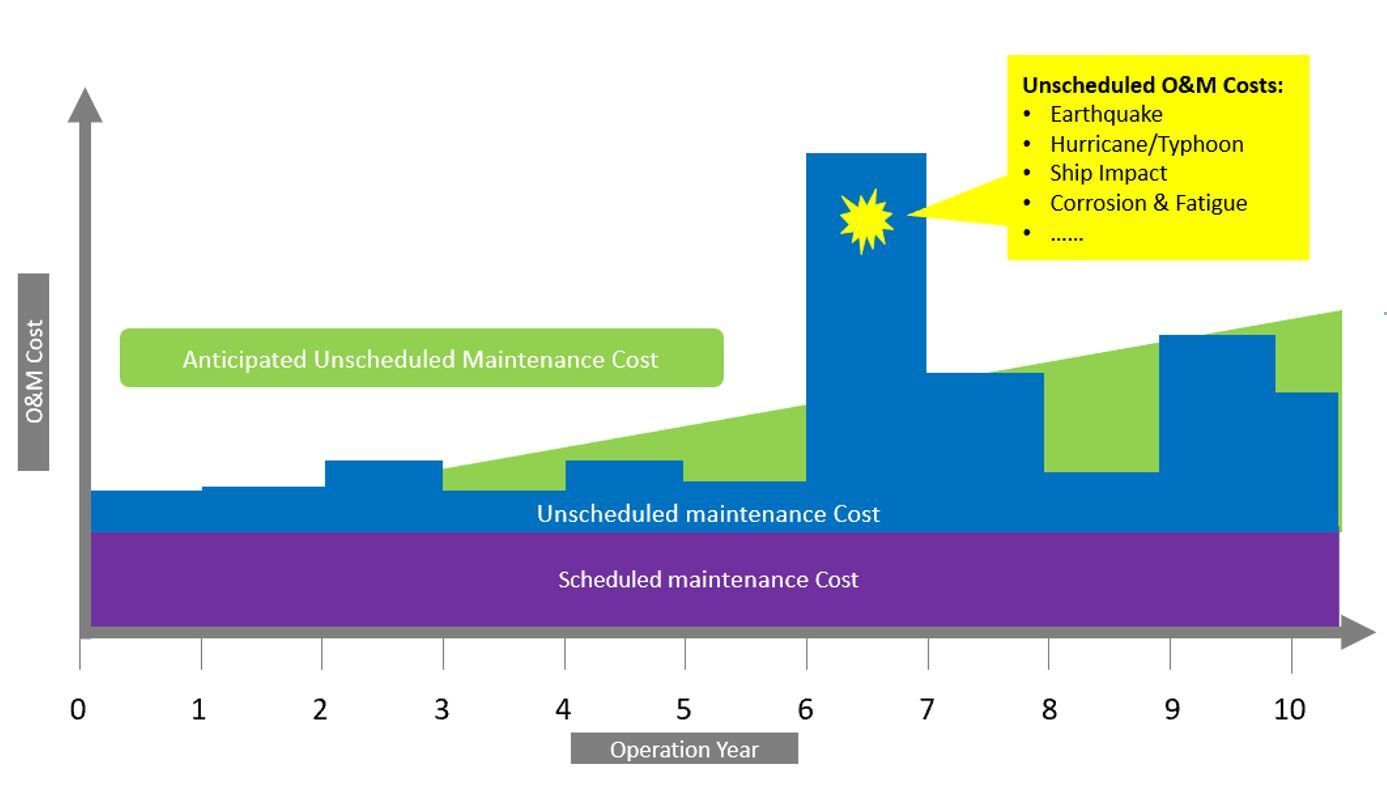

The O&M cost can make up around 30% of the levelised cost of energy (LCOE) of an offshore wind farm. O&M cost consists of scheduled maintenance cost and unscheduled maintenance cost. To minimise the scheduled maintenance cost and reduce the probability of the unscheduled maintenance cost, good understanding of structural risks is essential.

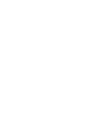

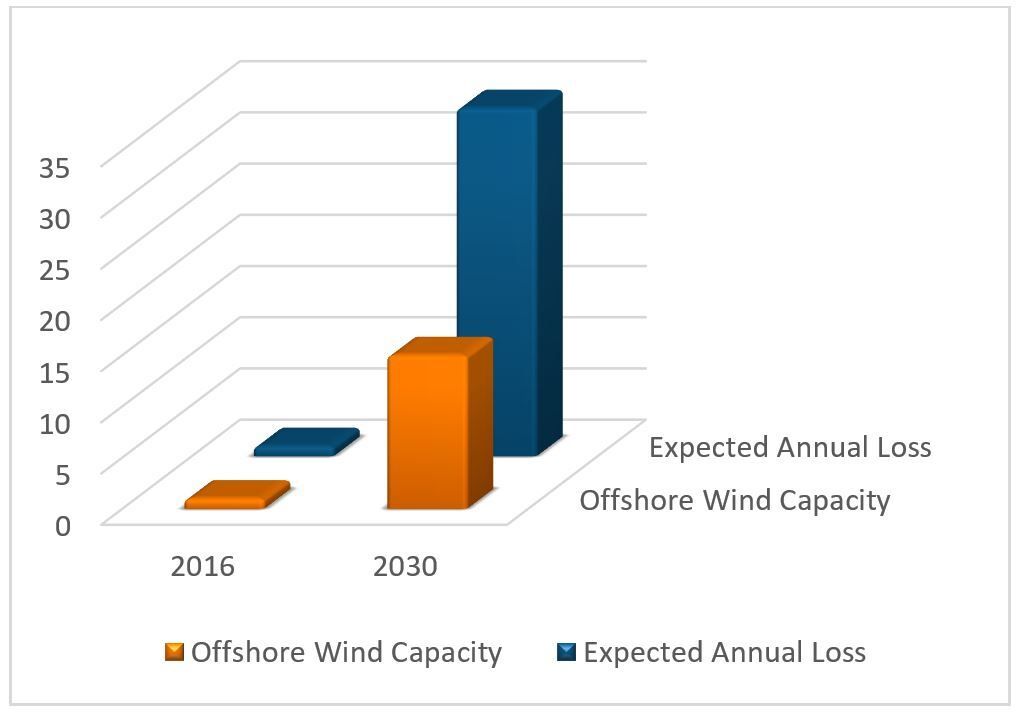

According to Swiss Re, by 2030, the expected average annual loss of offshore wind farm worldwide will be about USD 1bn. Even a 200-year return event could easily generate a loss of several billion US dollars. Between 2016 and 2030, the annual expected loss is projected to increase by a factor of 34, while the increased offshore wind capacity is expected to be increased by a factor of 15. The difference between the capacity and loss would be larger for the floating offshore wind as deep water floating wind structures have higher risks than the shallow water bottom-fixed wind structures. The risks areas include structural stability, corrosion and fatigue, ship collision, natural catastrophe and climate change risk.

Structural Stability

Nowadays, wind turbines are designed bigger and bigger for the increased capacity and power efficiency. For floating wind farm, aiming to capture stronger wind, the future turbine size would be even bigger than it is now. Take the world’s biggest 12MW turbine GE’s HALIADE-X for example, the rotor is 220 metres, the height from sea level is 260 metres, the head mass is 825 tonnes, and the tower (including monopile foundation) mass is 2,550 tonnes. For a top-heavy floating structure with dynamic loads from strong wind and wave, assessing structural stability and integrity under extreme scenarios are essential.

Corrosion and Fatigue

For offshore floating wind structures, corrosion and fatigue are the two main degradation mechanisms. Corrosion is caused by various factors, including humidity, temperature, oxygen concentration, acid water, etc. A fatigue crack initiates and slowly grows at a stress concentration hotspot, leading to the failure of materials. Fatigue life of a structural component is determined by cyclic loading, local geometry and material properties. Floating wind foundations are normally plated structures with extensive welded connections. Fatigue may govern the design. Special attention needs to be paid for corrosion and coating degradation on both internal and external structural components.

Ship Collision

Floating wind turbines are largely exposed to hazards associated with collision with either commercial or fishing ships, or support or maintenance vessels passing closely at high speeds. A detailed non-linear finite element analysis (NLFEA) for the floating wind hull structure can quantify the structural risk during the accident.

Natural Catastrophe and Climate Change

As floating wind turbines are installed farther offshore in deep sea, they are increasingly exposed to the risk of being hit by severe storms. The highest ever recorded wind speed was 408km/h with Hurricane Olivia in 1996 and the most severe storm in Scotland reached a top speed of 278 km/h, while offshore wind turbines are normally designed for resisting maximum 180 km/h gusts based on current industry standards. In addition, lots of evidence show that climate change is happening and leading to more frequent extreme weather events in the last two decades. For wind farm owners and insurers, an accurate structural risk profile would be essential to quantify the catastrophe and climate change risks of a floating offshore wind farm.

What is FOWSIM?

Floating wind turbines are normally certified or classified by offshore societies, such as DNV GL, LR, BV, etc. Structural integrity of support structure is one of key modules at all levels: prototype, sit type, project and in-service.

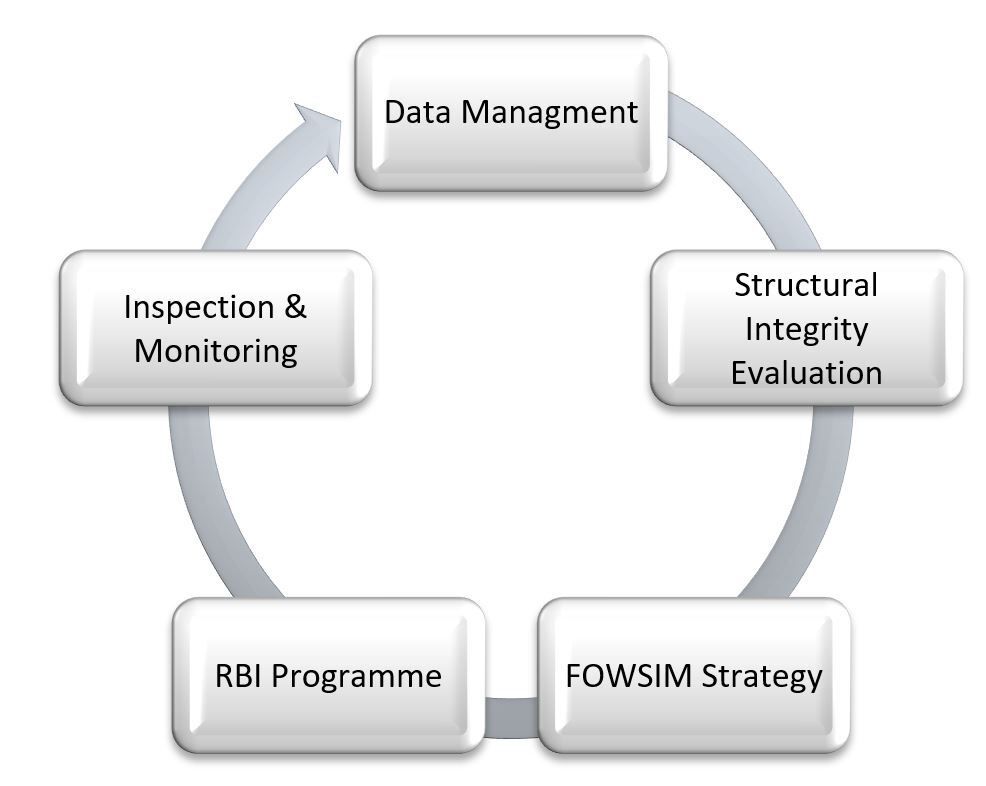

Structural Integrity Management (SIM) is a matured method and has been implemented in the offshore oil and gas fixed and floating installations for over two decades. As the floating wind structure prototypes stem from Oil and Gas offshore platforms, the SIM knowledge and experience from Oil and Gas floating facilities are also transferable to floating wind. Empire’s “Floating Offshore Wind Structural Integrity Management (FOWSIM)” system is derived from API-RP-2SIM but has been specifically tailored for floating wind foundations. The FOWSIM system includes five key elements: Data Management – Data Evaluation – FOWSIM Strategy – Risk-based Inspection (RBI) Programme – Inspection and Monitoring. A typical SIM process of floating wind unit is illustrated below.

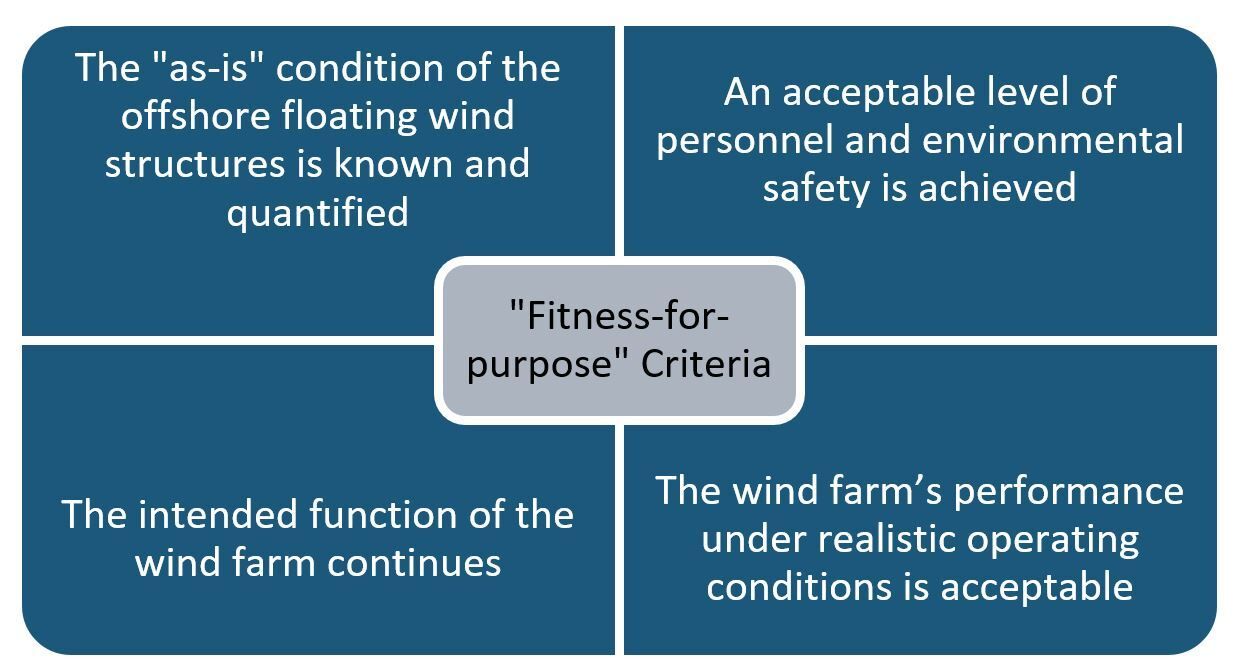

The objective of FOWSIM is to ensure that a fleet of floating wind structures are, and remain, ‘fit-for-purpose’ throughout their life, where such ‘fitness-for-purpose’ criteria is shown in below.

The philosophy of FOWSIM is to identify, manage and control the structural risks of floating wind assets by a proactive change management approach through life cycle.

FOWSIM can be considered as comprising two principal phases

The first phase is to ensure structural integrity for floating wind foundations at the completion of construction and commissioning. This is essentially achieved by the incorporation of inherent safety in the design using industry codes, standards, specifications and relevant good practice and using appropriate quality assurance procedures throughout the development, design, engineering, fabrication and installation activities.

The second phase is to ensure that such structural integrity is maintained throughout the operating phase of the asset’s lifecycle; this is essentially achieved by appropriate change management processes and, especially, monitoring and inspection to identify ‘reactive’ changes to the facility that result from aging, environmental effects, and operating activities.

A well-developed FOWSIM system will present an accurate structural risk profile of the floating wind assets, providing valuable information for stakeholders to accurately assess structural risks and make informed decisions.

How FOWSIM can help stakeholders to effectively manage the structural risks? More floating wind articles will be published on Empire Engineering soon.

Learn more about the Author, Empire’s Head of London Office, Aaron Zigeng Du.

Talk with a specialist

We've been a part of some of the worlds most exciting and

complicated projects in offshore wind.

If you need more eyes, brains and hands, we're ready to help.